Magnet Array Filtration

Magnetic Array Filtration, U.S. Patent # 7,662,282B2, is a patented circular array of rare earth magnets that are placed on the outside of any standard spin-on oil filter element. The iron based contaminates are then pulled from the oil flow and held against the inside wall of the canister. When it is time to change the spin-on element, the Magnetic Array Filter collar is removed and placed on the new element and the contaminates are discarded with the old element. This new patented technology dramatically improves the filtration capabilities of traditionally high absolute rated filters.

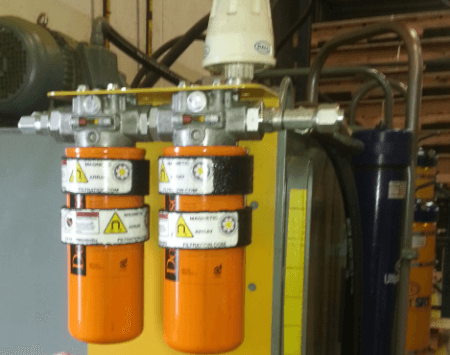

Shown is a hydraulic fluid filtration set-up for bulk supply provided by Fleenor Manufacturing utilizing two Donaldson filter elements and two 360MAFC collars each. This expedited the clean-up of several hundreds of gallons which normally took hours and multiple filter elements. By holding the small micron metals in the element, fewer $xx elements were needed.

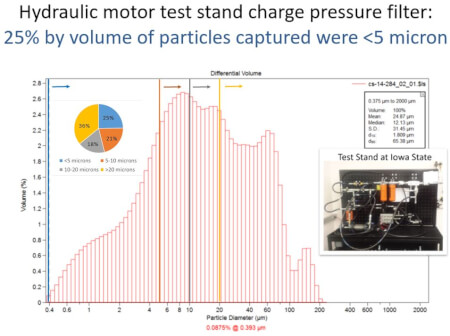

A 20 micron filter is designed to take out all debris greater than 20 micron yet maximize oil passage. The test above shows contaminated oil with 36% of the metal removed above 20 micron, with a whopping 64% of the metals captured too small for a 20 micron filter. 25% of the metal particles were even less than 5 micron - they do the most damage.

Another contaminated oil test, conducted by an Iowa State University Capstone Team, shows the rate of removing 4 and 6 micron contaminants compared against standard element, a 2pc competition, and the enhanced performance of 360MAFC regardless of filter orientation. 2 collars per filter can enhance the rate of cleaning the system.

• Removes metals from Engine & Hydraulic oil, & Diesel

• 25% of particles are <5 microns, passing most filters

• Reduce damage to Bearings, Sleeves, Gears, etc.

US patent 7,662,282 B2: Maximum Magnetic Array possible

Every system with metal pumps can benefit! Revolutionary to Hydraulic systems.

Bulk buy discounts available

Shown is a hydraulic fluid filtration set-up for bulk supply provided by Fleenor Manufacturing utilizing two Donaldson filter elements and two 360MAFC collars each. This expedited the clean-up of several hundreds of gallons which normally took hours and multiple filter elements. By holding the small micron metals in the element, fewer $xx elements were needed.

A 20 micron filter is designed to take out all debris greater than 20 micron yet maximize oil passage. The test above shows contaminated oil with 36% of the metal removed above 20 micron, with a whopping 64% of the metals captured too small for a 20 micron filter. 25% of the metal particles were even less than 5 micron - they do the most damage.

Another contaminated oil test, conducted by an Iowa State University Capstone Team, shows the rate of removing 4 and 6 micron contaminants compared against standard element, a 2pc competition, and the enhanced performance of 360MAFC regardless of filter orientation. 2 collars per filter can enhance the rate of cleaning the system.

• Removes metals from Engine & Hydraulic oil, & Diesel

• 25% of particles are <5 microns, passing most filters

• Reduce damage to Bearings, Sleeves, Gears, etc.

US patent 7,662,282 B2: Maximum Magnetic Array possible

Every system with metal pumps can benefit! Revolutionary to Hydraulic systems.

Bulk buy discounts available