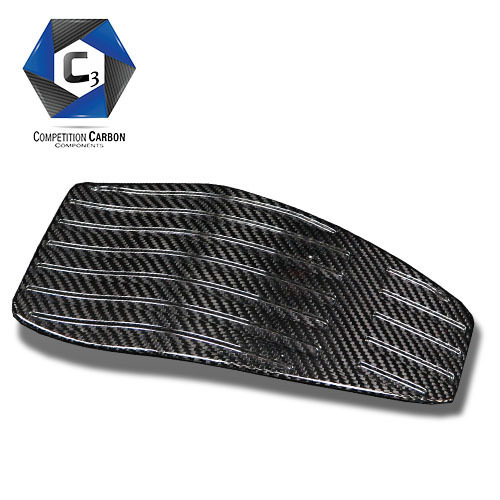

C3 Carbon McLaren 650S/MP4-12C Complete Engine Bay Kit

C3 Carbon is available for BMW, Ferrari, Lamborghini, McLaren and Porsche. Call today for pricing!

FREE SHIPPING on all orders!

FITMENT: All 2012-14 MP4-12C and 2015+ 650S

Nothing adds style to a McLaren quite like carbon fiber (that's the "C" in "12C", after all). Add drama and style to your McLaren MP4-12C or 650S with a completely new carbon fiber engine bay from C3 Carbon. All parts are direct replacements for the drab black plastic factory parts. This stunningly finished and easy to install carbon fiber engine bay perfectly reflects your McLaren's motorsports heritage.

Each autoclaved, pre-impregnated dry carbon fiber piece is engineered for a perfect fit and is finished flawlessly. C3 has matched the OEM McLaren 3K, 2x2 twill weave for a factory-original McLaren appearance. This a must-have for any 12C or 650S owner!

FEATURES:

Kit includes one each: C3-MCC12C-ECOV1, -ECOV2, and -ECOV3

Autoclaved pre-preg dry 3K carbon fiber with 2x2 twill weave matched to McLaren OEM carbon fiber

Clear-coated with automotive urethane, hand polished to a mirror finish

OEM-perfect fit

Digitally 3D laser-scanned for guaranteed fitment

Autoclave formed in billet aluminum molds at more than 100 psi and 200 degrees Fahrenheit

Experience the Difference of C3 Carbon Products:

Competition Carbon Components (C3 Carbon) has been steadily gaining in popularity among today’s high-performance driving enthusiasts due to several key factors that help C3 Carbon stand out in a market full of sub-par aftermarket offerings. Each C3 Carbon product is manufactured to provide perfect fit and extreme strength while reducing weight, maximizing quality and ensuring years of exceptional finish. We provide all of this for significantly less money than OEM parts.

Every product we make uses pre-impregnated dry carbon formed in a CNC-machined billet aluminum mold which is manufactured by laser-scanning the OEM component(s) so you know you’ll have a perfect fit, every time. Dry carbon is stronger and lighter than wet carbon, often weighing 1/3 of our competitors’ products. Our manufacturing methods also produce a smoother surface on each part for more dimensional accuracy; shaving edges, widening mounting holes and flexing pieces to make them fit are a thing of the past.

C3 Carbon also applies an automotive urethane clear-coat which is U/V cured for durability and guarantees C3 Carbon parts won't yellow over time.

Many of our competitors use wet carbon (which is heavier), and some use fiberglass with a carbon overlay (much heavier, as the carbon fiber has epoxy literally painted onto it). These materials and manufacturing methods produce a poor finish due to air contamination, and because the epoxy isn’t applied uniformly throughout the weave. These products are also much weaker than C3 Carbon products. Finally, most competitors use a fiberglass mold, which is far less expensive but cannot maintain the strict tolerances we demand of our own products. In the end, the fit and finish simply cannot stand up to C3 Carbon products