Formula One grade Castings

At Grainger and Worrall, we understand motorsport, and even more importantly, our motorsport customers. This includes your unique confidentiality requirements and need for high-integrity, precision sand castings- often quickly.

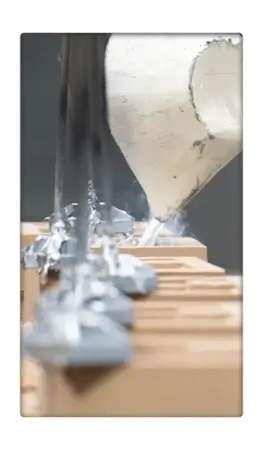

We've developed a specific roll-over casting process to produce the Formula One grade castings demanded by the motorsport industry.

With the largest independent foundry in the world, our engineers have been designing, manufacturing, and verifying complex precision sand castings for over 70 years. With a diverse range of product dimensions and an abundance of applications, our process involves the harmonisation of engineering and mathematical iteration to ensure a timely solution is delivered for every customer.

Our desire to innovate and improve the casting process for the future never dulls. While the challenge to be leaner, greener, and meaner increases each year, we’re committed to meeting these demands by pushing the boundaries of what is possible to produce high-quality castings that are lighter, more powerful, and more reliable.

To find out more about the sand casting process and the technology we use, click here.

- We use the flexibility of sand casting prototyping to create high-complexity, high-integrity castings, in a range of alloys to meet the high precision requirements of motorsport.

- We produce components such as cylinder heads and lightweight racing engines with sand casting.

- We use our experience in racing, rally engine and transmission programs to meet the demanding, compressed lead times required in motorsport.