Fully Variable VCR Crankshaft

Let’s get technial.

Realizing a true 4-stroke cycle

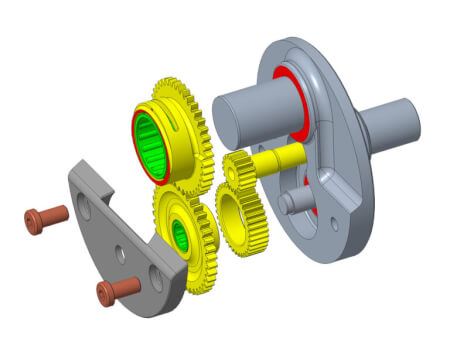

To create a true 4 stroke cycle with several efficiency improving functions the eccentrics are driven to continuously rotate around the crankpin at half the speed of the crankshaft. This means that in addition to the adjustment of the CR position of the eccentric in TDC firing, the eccentrics are always running around the crankpin with half the crankshaft speed.

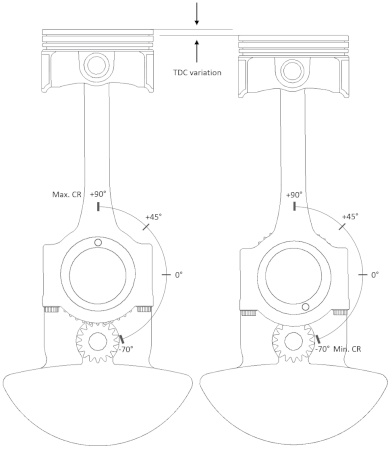

Difference in both TDCs within one cycle

Difference in both TDCs within one cycle

At max compression ratio the eccentric is in its highest position when in TDC firing, but one crankshaft revolution further the eccentric will thus be in its lowest position in TDC gas exchange. See cycle (5). This gives 2 advantages: 1 = internal EGR, 2 = it gives more freedom for the valves to move in TDC gas exchange.

Overexpansion

The eccentrics running at half the crankshaft speed means that the eccentric rotates only 180 degrees per crankshaft revolution. When the eccentric is at its mid-range position (0 degrees) in TDC firing it will be at its lowest possible BDC position at the end of the expansion stroke and at its highest BDC position at the beginning of the compression stroke (7) and thus creating true overexpansion.

Reduced intake stroke

In part load the intake stroke is reduced and the expansion stroke increased. When the eccentric is in its 45 degrees position (6) in TDC firing, the intake stroke is at its minimum and the expansion stroke at its maximum.

Maximum intake stroke in full load

When the eccentric is at its lowest position in TDC firing the intake volume is at its maximum (8).