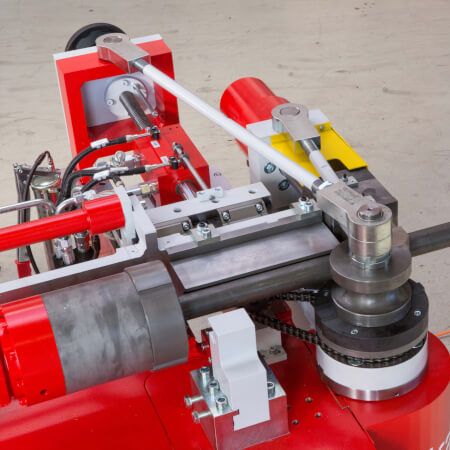

Transfluid 2060-3A CNC Mandrel Tube Bending Machine

The Transfluid 2060-3A-CNC is a robust CNC tube bender, perfect for roll cages, exhaust headers, handrails, and much more. The innovative servo-hydraulic system only runs when hydraulic pressure is required which reduces energy consumption by up to 70% and extends the life of involved components. The computer control stores virtually unlimited parts with up to 20 bends per part along with all required data to reproduce parts quickly and consistently. Once the tube is loaded, the operator can simply press the start button and create a multiple bend part completely hands-free. Typical 4-bend parts can be created in under 2 minutes.

Features include:

Windows based control with up to 20 bends per part

Features include:

Windows based control with up to 20 bends per part

10 foot bending length up to 3 inch OD, 20 foot bending length up to 2-3/8 inch OD

Controlled mandrel withdrawal

Following pressure die

Central lubrication of all movable parts

Mandrel lubrication

Tele-diagnostic system

Complete design, simulation and collision avoidance software

Optional STEP file import converter