CNC Machining Advantage

Quick-turn CNC machining works best for prototyping, form and fit testing, jigs and fixtures, and functional components for end- use applications. We have hundreds of high-speed CNC machines that manufacture parts on time, every time, so you can stay ahead of schedule.

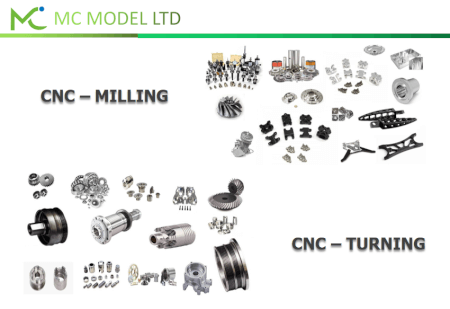

We use advanced equipment to offer you a variety of CNC machining services including milling, turning, EDM, wire EDM, surface grinding and much more.

Using our imported 3, 4 and 5-axis CNC machining centers, our skilled machinists can make turned and milled parts using a wide range of plastic and metal materials.

Our CNC machining abilities also complement our 3D metal printing service making us a great one-stop-shop for your advanced designs.

CNC machining is great to meet a range of your product development needs. Here are some of the benefits of precision machining:

1, Quick removal of large amounts of metal material

2, Highly accurate and repeatable

3, Suitable for many different kinds of substrates

4, Scalable volumes from one to 100,000

5, Low investment in tooling and preparation costs

6, Economical & Fast turnaround

We use advanced equipment to offer you a variety of CNC machining services including milling, turning, EDM, wire EDM, surface grinding and much more.

Using our imported 3, 4 and 5-axis CNC machining centers, our skilled machinists can make turned and milled parts using a wide range of plastic and metal materials.

Our CNC machining abilities also complement our 3D metal printing service making us a great one-stop-shop for your advanced designs.

CNC machining is great to meet a range of your product development needs. Here are some of the benefits of precision machining:

1, Quick removal of large amounts of metal material

2, Highly accurate and repeatable

3, Suitable for many different kinds of substrates

4, Scalable volumes from one to 100,000

5, Low investment in tooling and preparation costs

6, Economical & Fast turnaround