April 3rd 2024

Firestone Liberia Earns Historic Certification: The World’s First ISCC PLUS Certified Natural Rubber Farm

Bridgestone Americas (Bridgestone) today announced its Firestone Liberia natural rubber growing and processing facility earned the International Sustainability and Carbon Certification (ISCC) PLUS recognition. The Firestone Liberia facility is the world's first natural rubber farm to achieve the ISCC PLUS certification.

The Firestone Liberia facility earned the ISCC PLUS certification for its efforts in reducing environmental impacts, utilizing resources efficiently and enhancing its capacity to adapt to, mitigate and build resilience to climate change. The certification also recognizes the farm for the implementation of good agricultural practices, ensuring proper working conditions, complying with local regulations and fostering effective management practices to facilitate ongoing growth and improvement.

“As we progress in our transformation to a sustainable solutions company, we are making incredible progress toward sustainable manufacturing,“ said Rick Burnett, Vice President, Internal Manufacturing Division, Bridgestone Americas. “The ISCC PLUS certification is a pivotal milestone which recognizes our actions to sustainably growing and processing natural rubber as we accelerate our progress toward using 100% sustainable materials2 in our products by 2050.”

The Firestone Liberia facility is the largest contiguous natural rubber operation in the world, covering approximately 118,000 acres or 185 square miles. The facility is also Liberia’s largest private employer with approximately 4,000 teammates who harvest and process natural rubber. The company also plays an active role in the Liberian community by providing teammates and their dependents free medical care and operating 23 schools, which educate more than 7,000 students.

After processing, the natural rubber is shipped to Bridgestone’s tire plants in North America and Europe for the manufacture of tires. This includes Bridgestone’s flagship EV touring tire, the Bridgestone Turanza EV, which incorporates 50% ISCC PLUS-certified recycled and renewable materials and are manufactured using synthetic rubber2.

The facility’s ISCC PLUS certification represents a major stride toward the company’s 2050 goals, which include achieving carbon neutrality and producing tires exclusively from 100% sustainable materials3. Bridgestone also continues to advance its R&D efforts aimed at diversifying the world’s natural rubber supply including commercializing the use of guayule natural rubber in tires.

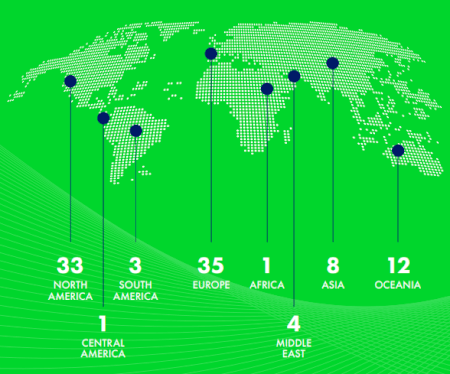

The Firestone Liberia facility is Bridgestone’s 16th facility or organization to earn the ISCC PLUS certification since 2022. Notable certifications include: the Firestone Polymers Polymer Engineering Pilot Center, which is the first ISCC PLUS certified Bridgestone polymer plant and the Aiken County Passenger/Light Truck Radial tire plant and Wilson, N.C. Passenger/Light Truck tire plant, which are the first two ISCC PLUS certified tire plants in America. The ISCC PLUS certification of the Firestone Liberia natural rubber growing and processing facility aligns with the “Ecology” values of the Bridgestone E8 Commitment. The Bridgestone E8 Commitment, encompassing eight values all beginning with the letter “E”, solidifies Bridgestone’s dedication to fostering a more sustainable world.

For more company news, visit BridgestoneAmericas.com.

1 The bio-based and recycled material sourced for the natural rubber is allocated using the ISCC PLUS mass balance approach. With respect to sustainable materials handled by the certified site, the annex to the ISCC certificate provides additional information and states that it is only applicable for material handled under the scopes: farm/plantation, point of origin, central office, (farm/plantation or point of origin) first gathering point, processing unit (any type) but not for material that is only traded and/or stored). Mass balancing is a chain of custody option in which certified and non-certified materials are mixed physically but kept separate in the bookkeeping. This method is used to document and track biological, circular and renewable materials through complex manufacturing systems. By using mass balance, certified entities can track how much sustainable material has been used in their manufacturing systems and ensure that it corresponds exactly to the amount of certified content in the end products. Specific information about the ISCC certification is available at: All Certificates › ISCC System (iscc-system.org)

220% natural rubber; 18% recycled (circular) synthetic rubber; remaining recycled (circular) carbon black. ISCC-certified circular butadiene rubber, styrene butadiene rubber and carbon black allocated using the ISCC mass balance approach. For more details about ISCC, please go to www.iscc-system.org.

3 The Bridgestone Group defines sustainable materials as those that:

1. Come from resources with a continual supply;

2. Can be used as part of the Group’s business over the long term; and

3. Have a low environmental and social impact over their lifecycle from procurement to disposal.

For more Industry News, please Click Here

For more Industry News, please Click Here